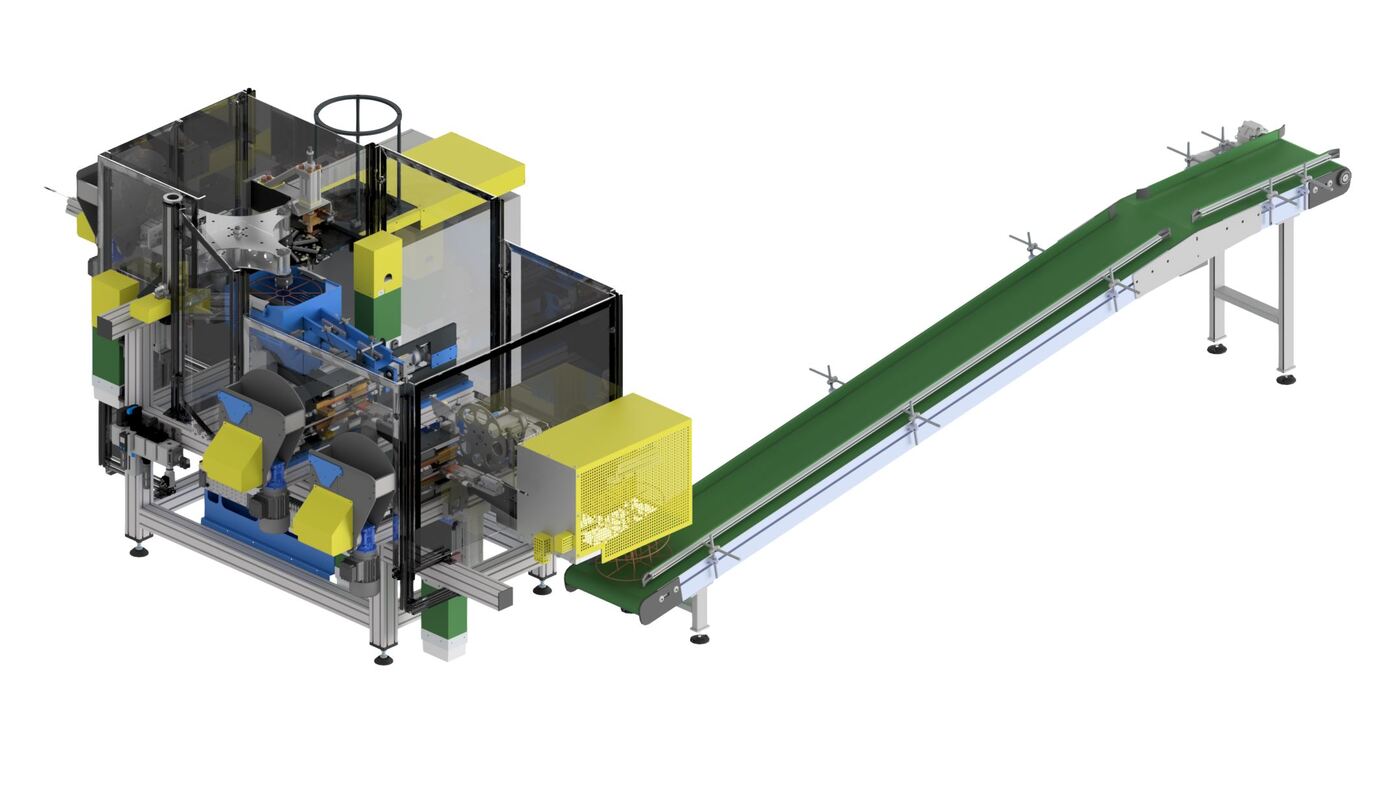

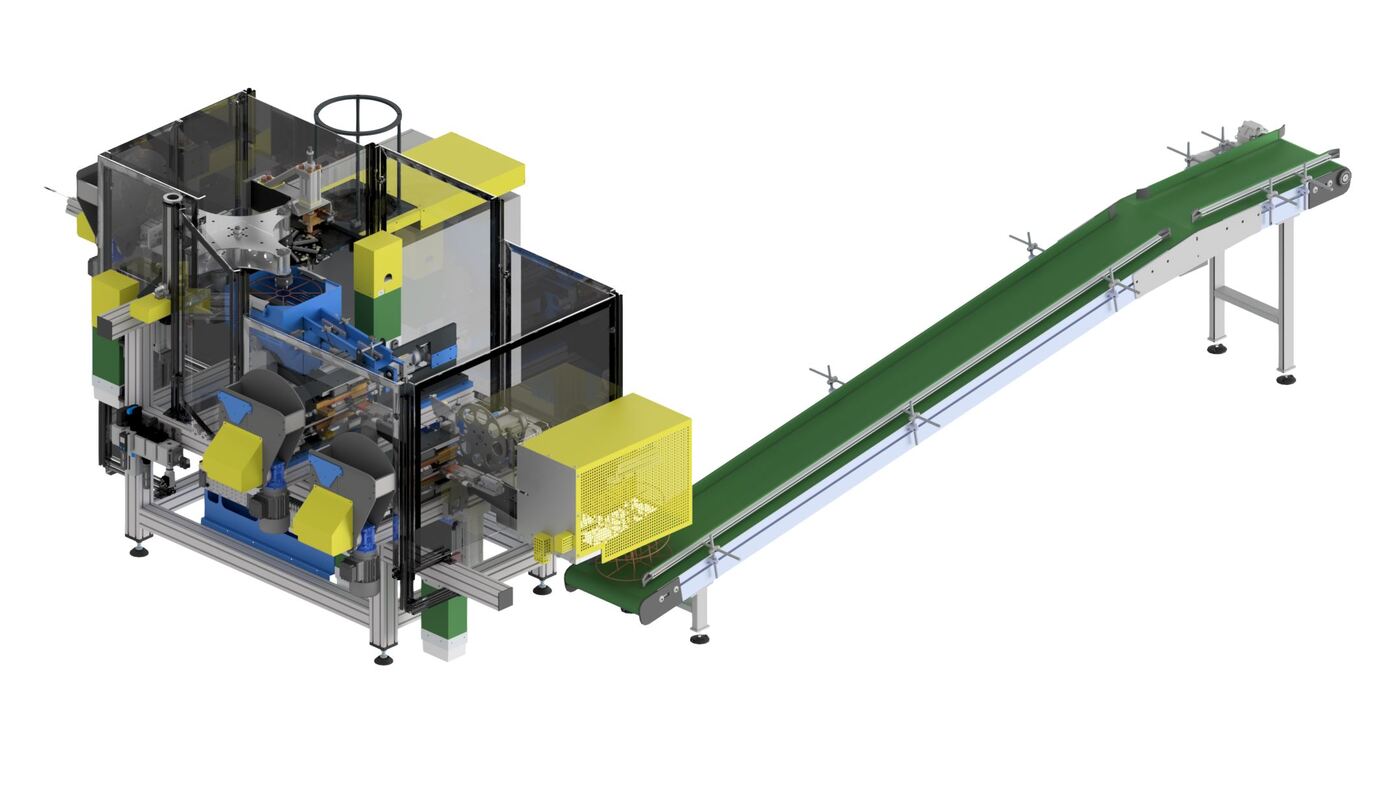

Assembly Machine GT4000 2023

Assembly Machine GT4000 2023

Description

The machine is run fully automatically controlled by a PLC system, which is placed in a metal cabinet together with four electronic welding controllers and five servo motor drives.

The machine is divided into stations. A carousel feeder automatically supplies the first four stations.

Station 1

This station contains the magazine for the 60 mm rings (center ring).

Station 2

Magazine for spokes that automatically supplies the welding unit. The welding unit attaches the spokes to the center ring.

Station 3

Contains the magazine for the 300 mm rings (outer rings), and a welding unit to weld the outer ring to the spokes on the center ring.

Station 4

Spoolside magazine for Stn.#5 that contains two pieces.

Station 5

Welding station for assembling the spoolsides with the spokes. Also containing the magazine for winding spokes.

Station 6

Welding station and a magazine for center spokes.

Station 7

A belt transports the spools in a different place, to be palletized.

Technical Data

Diameter

inside

52/54 mm

Max overall diameter

300 mm

Overall width

100 mm

Max carrying capacity

18 kg

Max winding volume

270 mm

Wire diameter range

4 mm

Power (welders)

4 X 17 kVA

Total net weight of the machine

1,185 kg

Air installation

R 1/2″ 7 bar

Overall dimensions

3250 (4m) x 2850 x 1850 mm (LxWxH)

Electrical requirements

TN-S 400/230 Vac 50/60 Hz 63 A

Outputs (spools/minute)

3