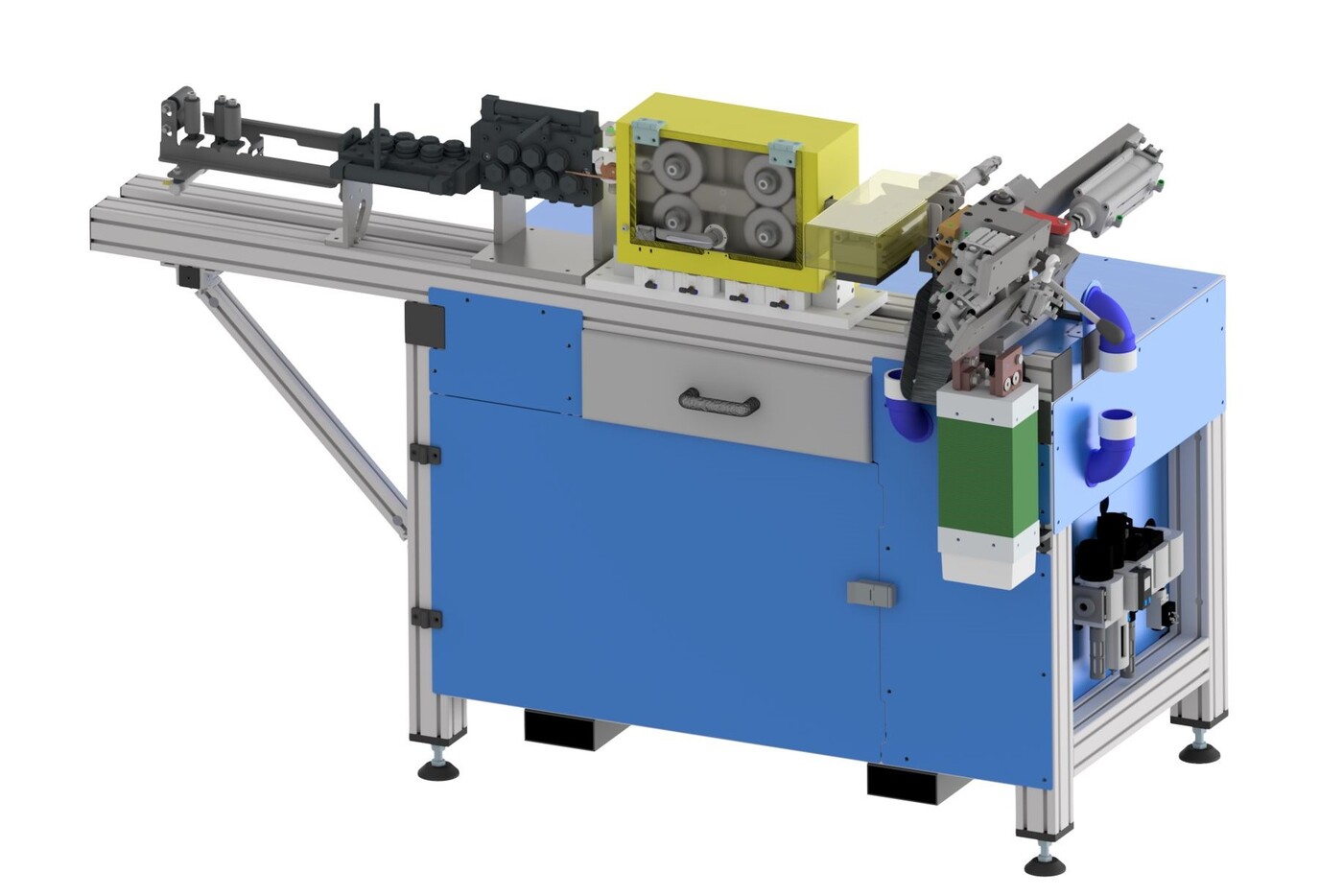

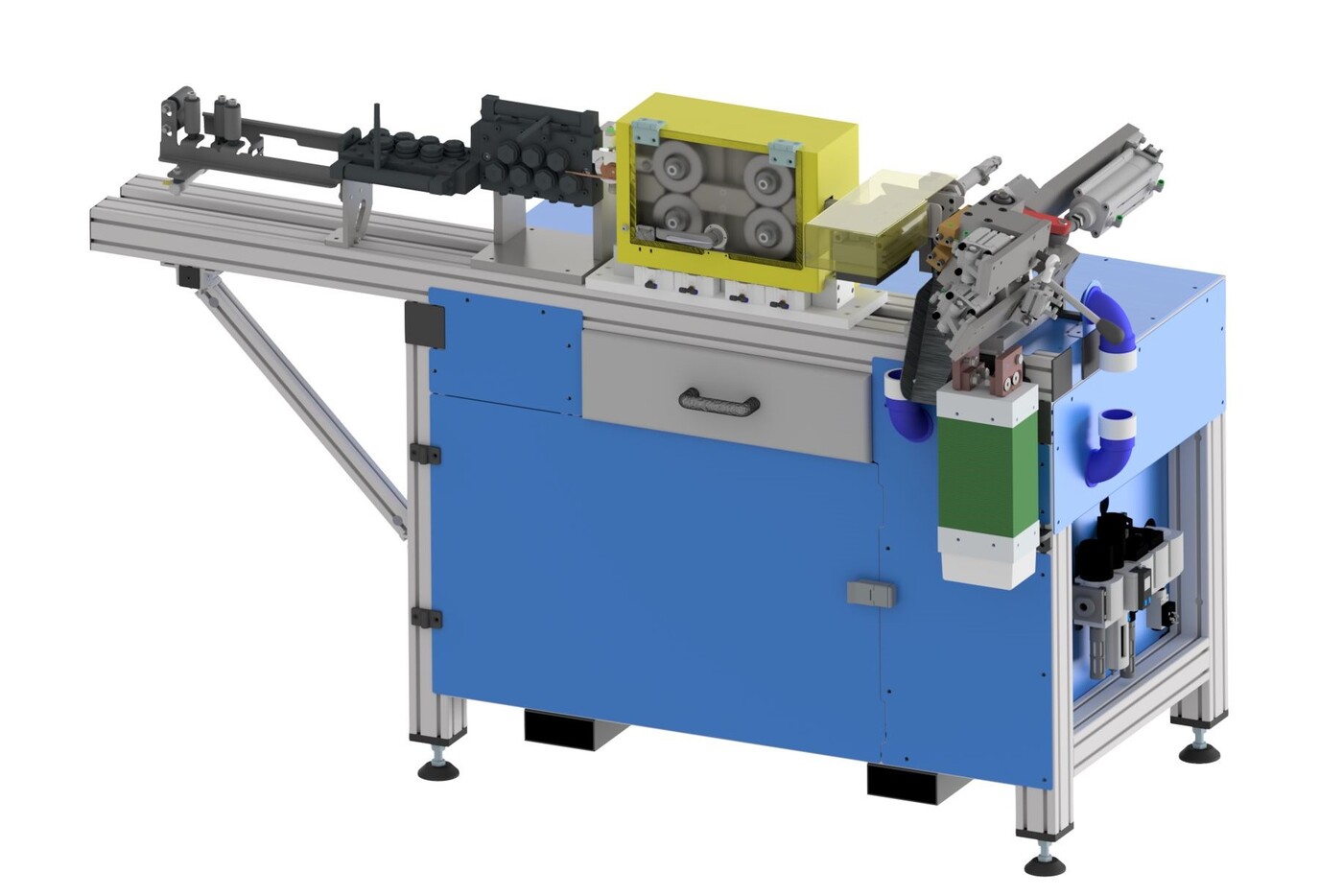

Ring Machine GT6000 - 60

Ring Machine GT6000 - 60

Description

GT6000-60 manufactures steel rings that are used to produce BS300 coils. The machine fully automatically produces wire rings for the Spool Assembly Machine. The machine is fed by a wire drum, which is taken off from a decoiler. The wire is straightened by an independent roller device and fed into the bending rolls by a roller feeding device, driven by an electric servo motor.

After a completed feeding, the ring is cut off, and transported into the welding unit for welding. At the end of the welding cycle it is released and dropped from a chute. When the welding is completed, the ring is removed from the welder.

The machine is run fully automatically controlled by a PLC system, which is placed in a metal cabinet together with an electronic welding controller and two servo motor drives.

Technical Data

Ring diameter

60 mm

Wire diameter range

4 mm

Power (welders)

1 x 17 kVA

Total net weight of the machine

450 kg

Air installation

R 1/2″ 7 bar

Overall dimensions

1500 x 850 x 2000 mm (LxWxH)

Electrical requirements

TN-S 400/230 Vac 50/60 Hz 35 A

Outputs (rings/hour)

1200